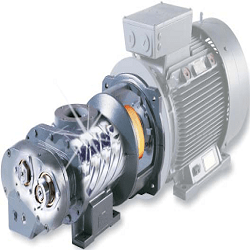

These highly efficient rotatory screw compressors produce air and gases in larger volumes and higher pressures than the piston compressors. Rotatory screw type air compressors are the best choice to replace piston compressors for achieving bigger operational efficiency and greater industrial applications. Pryes compressors is the leading Rotary Screw Compressor manufacturer in India. PRYES, Rotary Screw Compressor manufacturer in Tamil Nadu, manufacturing all variant compressors which can be used for hefty industrial mechanisms that require gases in higher volumes and pressure.

We are the leaders of the screw compressor market as we provide our air compressors in world-class reliability. We also specialize in the manufacturing of both Oil flooded Screw Compressors and Oil-Free Screw Compressors. Oil flooded Screw Compressors use an oil-injected system for preventing the formation of rust inside the drum and components of the rotary screw compressor, then the oil contamination of air output is separated using an oil separation system which is mounted with the screw compressor.

You can avail any type of screw compressor based on your budget and requirements since we offer compressors with different output and efficiency levels. These types of screw air compressors are also highly capable of producing continuous air supply for flawless industrial functions. Still in Pryes compressors, we manufacture rotatory screw air compressors in various horsepowers (HPs) to meet various compressed air demands for your particular industry. On the other hand as we are the best compressor company in India, our screw compressor maintenance is very low when comparing to the other brands. Because we use the finest screw compressor parts and screw compressor spare parts that are imported from international brands. So Our screw compressors are easy to install due to our compact designs and they are highly safe to handle, maintain and operate.

Super premium efficiency

Super premium efficiency

Vibration free

Vibration free

Designed for

Designed for

Service friendly

Service friendly

Direct drive

Direct drive

Advance PLC

Advance PLC

Lowest oil

Lowest oil

Lowest life

Lowest life